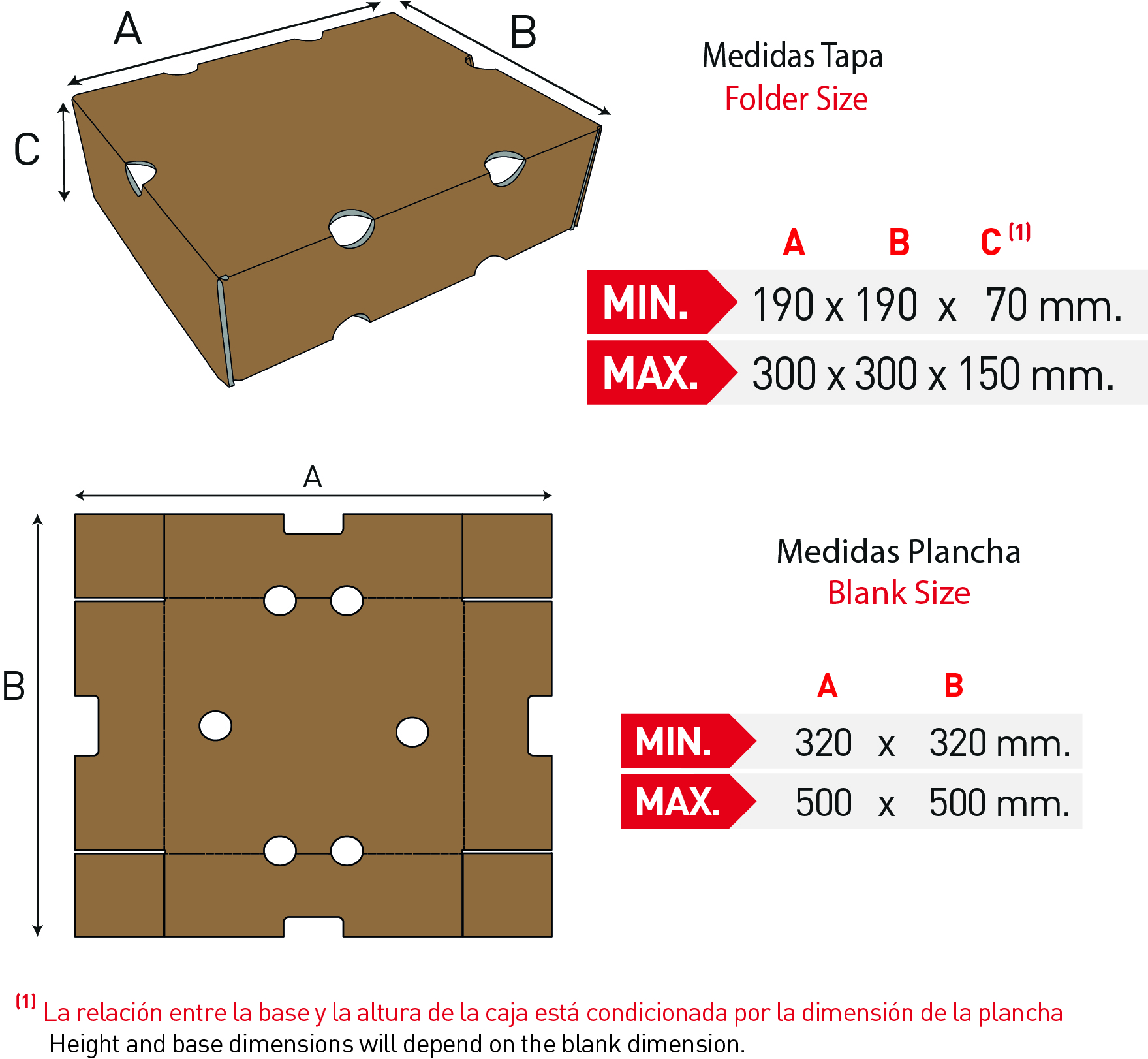

HAT Mini is a cardboard box lidding machine, specially developed to

lid boxes of different heights. The difference with the other

HAT machines lies in the size of the cartons it can handle, as it can lid cardboard boxes up to 190 x 190 x 70 mm in height. The main advantage offered by these machines is that by

closing or lidding boxes with Hot-Melt, they help prevent multiple issues with your products, such as deterioration, contamination, theft or loss.

- High Production can reach up to 1,300 boxes/hour.

- Operation: it has servos to control the movements.

- Lid Storage: 1.5 meters (high working autonomy).

- Flexible: It can lid different types of boxes (Bliss or C-1).

- Glue time: adjustable from the machine screen.

- Adaptable: designed for integration with production lines.

- Especially used in sectors such as cherries, meat, cosmetics, winery and e-commerce.