Description

- Hot Melt Timer: lets you program the glue equipment daily at an appointed time. It also has a standby function that will be activated when the machine has not run for a predeterminated time to reduce the temperature of the glue tank automatically.

- Touch screen: The machine has a colour screen for programming which allows: program selection, change of designs and sizes, language selection, maintenance, problem identification, production statistics, etc. allowing to control all machine processes.

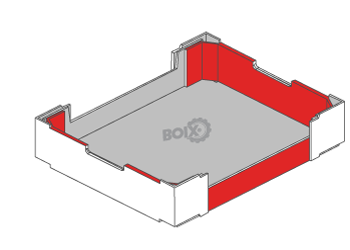

- Double Wall Kit: All three versions can form the double wall in the board feed direction.

- Upgrade: There is an upgrade kit that transforms both an FP-4/2M1 or an FP-4/2M2 in an FP-4/2M3.

- Security: all safety devices are double circuit CE safety level “C”.

- Evaporator: mounted inside the machine to ensure a uniform flow, capable of a high production without any vibration. Inside it is a drain valve which purifies the condensed water so that it doesn’t accumulate and reach the valves and cylinders.

- Air Pressure: The centralized control is regulated from the same panel. A monitoring pressure switch prevents the machine from operating with incorrect values.

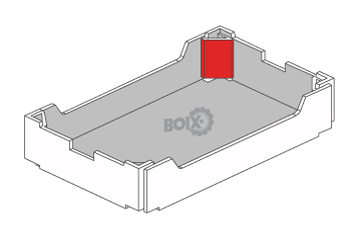

- Central Section: The central section of the machine (where the columns are formed) has a pneumatic lifting system to facilitate the removal of the blanks which could be damaged, quickly, easily and effortlessly.