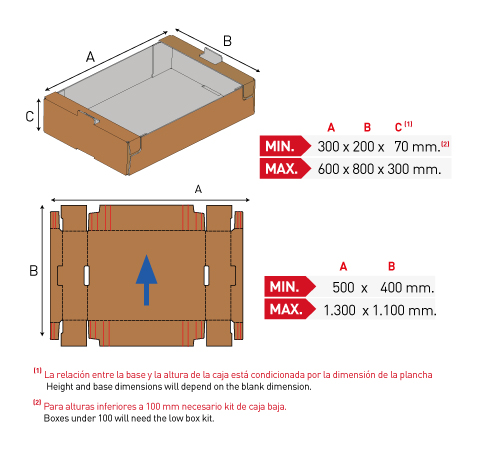

Description

- PROGRAMMING THROUGH simple and user friendly TOUCH SCREEN.

- LOADING IS DONE FROM THE BACK.

- blank by blank.

- Extraction by means of a Festo Ovem vacuum generator with suction cups.

- Automatic blowing function on the suction cups for cleaning.

- BLANK INTRODUCTION IS AUTOMATIC AND USES:

- A new pusher system.

- Control of the Jog movements by screen.

- It is not necessary to use the crank handle.

- MACHINE WITHOUT MECHANICAL CLUTCH:

- Pusher control by PLC and Variable Speed Drive.

- STOP AND START BUTTONS ARE SEPARATE.