Description

- Operation: it has servos to control the movements.

- Lid Storage: 1.5 meters (high working autonomy).

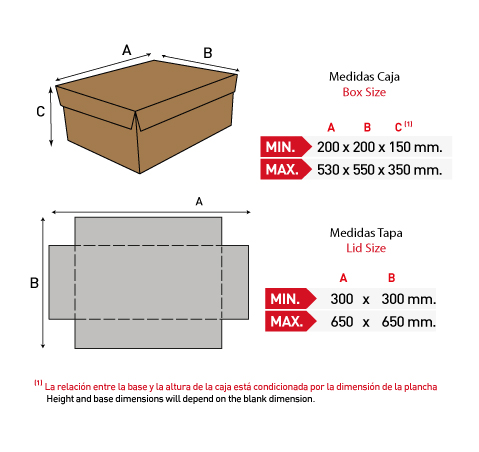

- Flexible: Can cover different types of boxes (Plaform, Bliss or C-1).

- Gluing time: adjustable from machine screen.

- Adaptable: ready for integration in production lines.

- Operation: box separation system (prevents boxes are pushed).

- Automatic: automatic detection and adjustment of box height.